Gripple is a serial innovator. The business was established in 1989 to manufacture an ingenious means of joining agricultural wire fencing together.

Gripple is a serial innovator. The business was established in 1989 to manufacture an ingenious means of joining agricultural wire fencing together.

Three decades later and the Sheffield-based organisation is a globally recognised innovator delivering value-added solutions to the construction, landscaping and agricultural markets. In fact, 25% of its turnover is generated from products developed in the previous five years. Of those recently developed products, one of the most innovative is the Fast Trak® suspension system.

Fast Trak was developed in response to customers' demands for a fast and versatile system capable of supporting both mechanical and electrical containment systems.

Building services – the systems that make buildings functional and safe – include piped services for heating, cooling, water and drainage, together with electrical and data cabling.

These services are distributed around the floors of the building, usually above the false ceiling, by suspending them from the soffit of the floor above.

The conventional way to do this uses concrete anchors drilled into the soffit, followed by the use of a threaded rod and channel system. Every element of this needs to be carefully measured prior to the rods and steel channels being cut on site. It’s time consuming, uses potentially hazardous techniques and is open to inaccuracy.

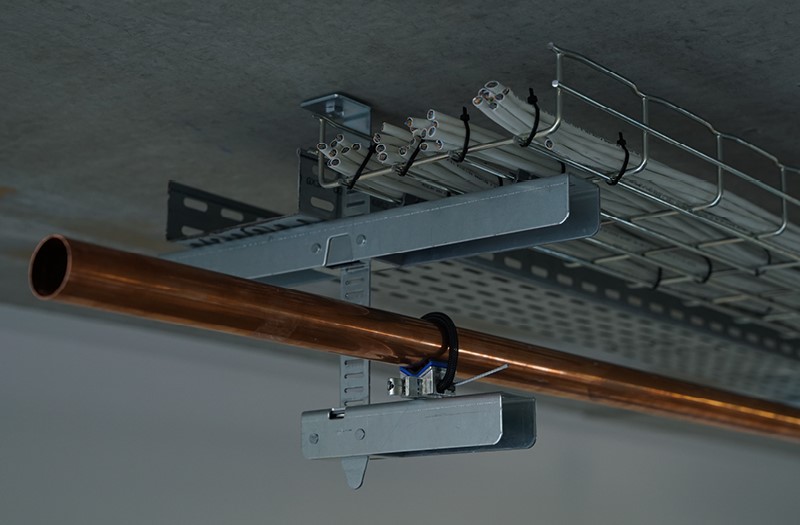

Gripple’s answer is a prefabricated bracket system. Prefabricated tracks are attached to the concrete anchor system and hang vertically from the ceiling. Tracks have fixing points for the brackets, ensuring level and accurate installation and the brackets are secured with safety locks, ready for the immediate installation of ductwork, cable containment or pipes.

The whole process has been demonstrated to be as much as six times faster than traditional installation methods and reduces health and safety risks on site. No cutting of metal elements is required and the tracks themselves can be folded neatly underneath the bracket. No need for ‘hot works’ on site and zero site waste is generated.

This robust system is available in numerous sizes and with various mounting systems to make it suitable for a broad range of applications, including fire-tested solutions. Fast Trak is delivered to site as a complete, ready-to-install solution, eliminating the need for cutting on site and reducing packaging and vehicle movements and requiring fewer materials to be stored on site.

Having successfully launched Fast Trak, Gripple then developed Fast Trak Side Loading in response to demand from electrical contractors looking for a lighter and even quicker-to-install suspension system.

Fast Trak Side Loading comprises a single bracket supported from a single, central track making it, effectively, an L or an upside-down T suspension system, depending on the point from which the bracket is suspended. The central support allows cable trays and baskets to be loaded from the sides.

The Gripple Fast Trak system was used in the Taff Vale project, comprising three buildings – a community building, offices for let and a headquarters for Transport for Wales.

Kevin Watts, Electrical Project Engineer for building services consultant Briggs & Forrester: "We looked at Gripple as an alternative to the traditional rod and Unistrut system and are using Fast Trak predominantly for the containment throughout."

BIM models were supplied to Gripple who were able to design the system around everything that was in place, making sure there were no clashes with any other services and ensuring that all the bracketry fitted.

Installation was straightforward and fast. “Using Fast Trak on this project has saved us quite a bit of time on the install" continues Watts. "There’s about 120 brackets in total for the containment system and that was installed in a day.

"Also from a health and safety point of view it takes away a lot of the cutting and also head strikes as well when you’re working above the system, because the whole system folds neatly inside the bracket."

"I would recommend Gripple to other users and I would be interested in using it again on future projects definitely."